10/26/2016

|

|

|

Previous Page | Next Page | Table of Contents click pictures for a larger version More Sails and Control Ideas

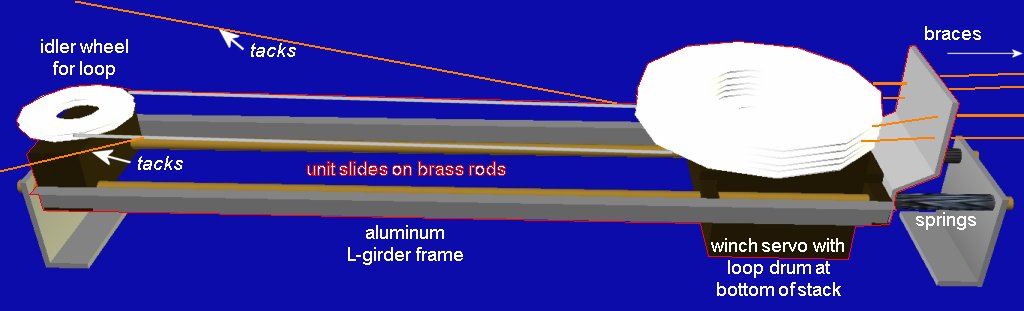

I initially considered controlling them with an additional drum on the winches, but realized that wouldn't work because of the slack - the tacks would come off the drums and tangle everything.

Anyway, where the course sails are concerned, none of this needs constant tension to be maintained as the drawing may imply, the sheets can be given some slack, but too much slack gives the lines opportunities to snag on exterior details; anchors, catheads, etc. I'd need two of these to separately control the main and fore. This adds two expensive servos, and the space these units would take up. The standard drum is about 2" across, and to pull the 11"-14" of my tacks, using doubling, would require the units to be about 7"-10" long, and about 3" tall at the servo end? Plus dealing with the other control lines nearby, specifically my jib-sheets. I think each unit could simply be Y-ed off the existing winches and that should synchronize the tacks and braces on each mast all by itself. I did consider the possibility this could be built into the existing sliding winches, running a loop on the same drum with the braces and eliminating additional servos. The whole loop mechanism would move with the winch as it maintained tenson on the braces. With the braces pulling one way, the tacks pulling another, and the springs pushing yet another, I'm not sure if this would work with all that going on. I'll have to mock it up and see.

So, while I think that all would work quite nicely, it's far more expense and effort than I can manage right now In the meantime; I think I will just go for the Bentinck-boom set-up. A Bentinck-boom is simply a spar attached to the clews of the course sail. They were commonly used by British merchant vessels in the second half of the 19th century. I'm not aware of it's use on warships at all. So, instead of using a spar, I would insert a stiff wire rod into the foot of the sail, bent to match the sail's shape. etc. This basically places a yard at the bottom of the course, and is how the SC&H models handled the course sails. There are two other options I can think of. Dan used two rods from the center of the course yard down to the clews, disguised as clew garnets, to hold the clews out on his Syren's fore course. The other variant of this is to insert rods into both side seams of the sail, anchored in the course yard. The issue with both of these methods is they don't allow the sail to billow up or lift. I'm not really sure which option I'll go with at the moment - I want something I can easily undo to let me bunt up the courses to shorten sail, so I'll have to experiment a little to decide. Prep to Sail 10/24: I really want to sail the model before it gets cold, so I've been jury rigging her not only to test fit and function, but to get her operational enough to, well, operate. This was going to be the first sail with separate controls for fore and main/mizzen, but I don't have two winch drums, so I'm falling back on my mock-up drum again. This sail will have several "goals;"

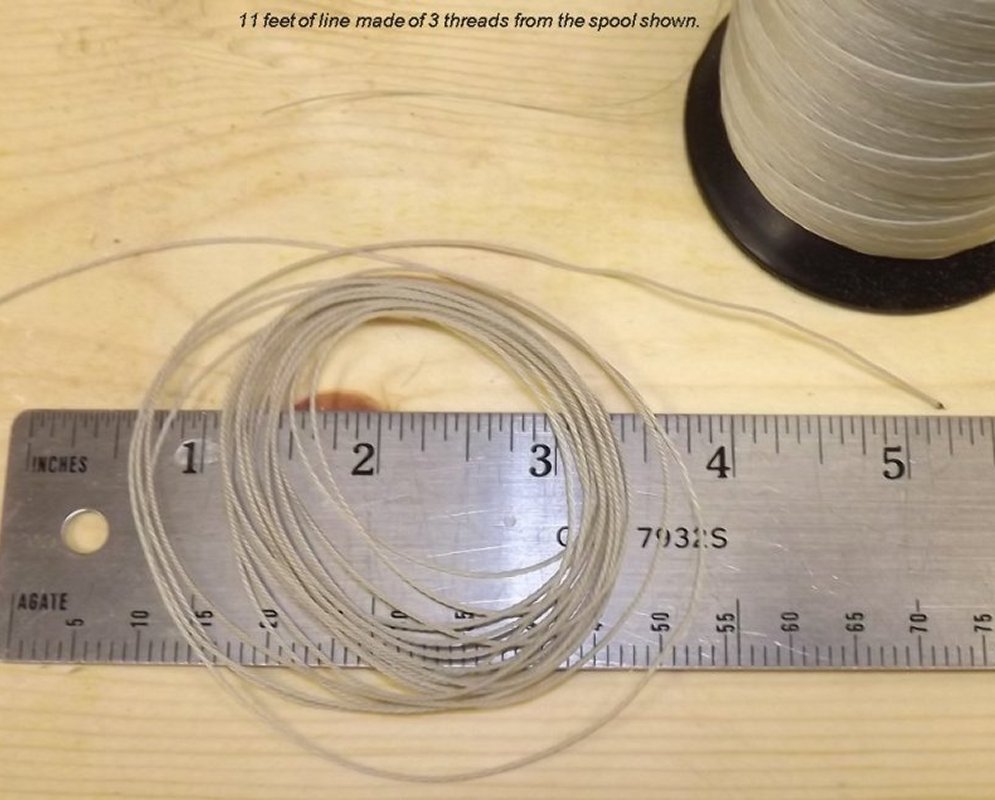

As the brace comes down from the yard it goes to a block on the mainstay that turns it down toward the deck. I found this routing interfered with the travel of the main yard and corrected this by hanging a pair of blocks under the main top to clear the yard. I spun up more Dacron line for the heads'ls and got two more 12 foot lengths before the rope-walk broke. As a result I just used one strand of Dacron thread for the driver sheet, and just sheeted the fore-topmast-stays'l to center. Once in place, and appearing to work, I made a couple of quick videos to demonstrate it: Today the wind is supposed to be Northerly at 5 mph, though it looks like more than that in the trees outside my window. It's time to try and stuff the old girl into the car and take her over to Mark's where we'll put her in Rock Creek and see how she does. |

||

|

|