7/14/2022

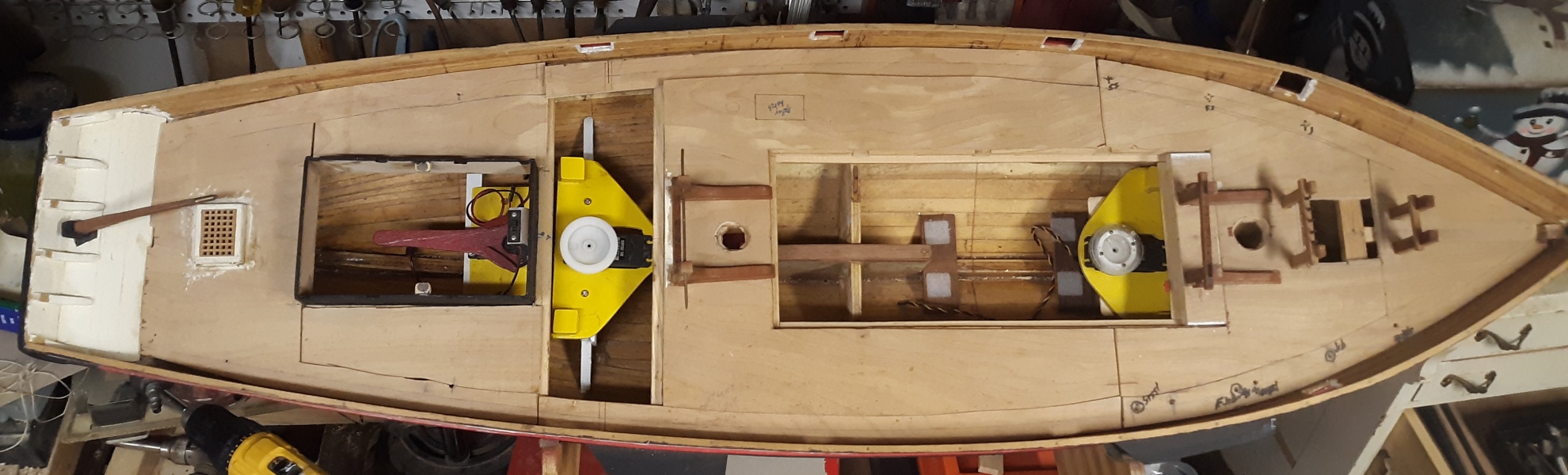

Previous Page | Next Page | Table of Contents 6/22/2022: Another Course Change Mark sailed his 46 inch schooner Cliodhna (Clee-na) for the first time in the pool at National Maritime Day. He controls the sails with a sort of clothesline system driven by winch servos. It's actually a common systen in RC models, especially schooners, and what I originally intended to use in Pride. The winch drives a closed loop or circuit, and the sails sheets are attached at points so the loop's travel pulls the sheets, or whatever else, the requisite amount for each sail. Mark used one loop to control the over-lapping jibs, and the other loop controls all the rest of the sails. Watching this work so well in the pool, especially with the over-lapping jib, I started rethinking Pride's set-up. One thing I'd already planned to do is remove the drive-motor. There's no way that a 1 inch prop is going to move all that sail in even the slightest breeze. The motor will go to the upgrade of my rope-walk. 6/25: With the motor gone, the rudder servo will be moved aft past where the motor was into the Cabin hatch enough that I can access the screw that holds the servo-arm. The winch servos with be re-mounted, one just forward of the rudder servo, and the other just behind the foremast, with their loops running opposite of each other. This set-up should have enough length to control everything, even, the square sails. The old engine bulkhead and the blocks the rudder servo was mounted on, I'll try to use in mounting the winches; being epoxied in, they'll be difficult to remove. 6/27: Took out the prop shaft and cut back the stuffing box/tube plugging it with epoxy.

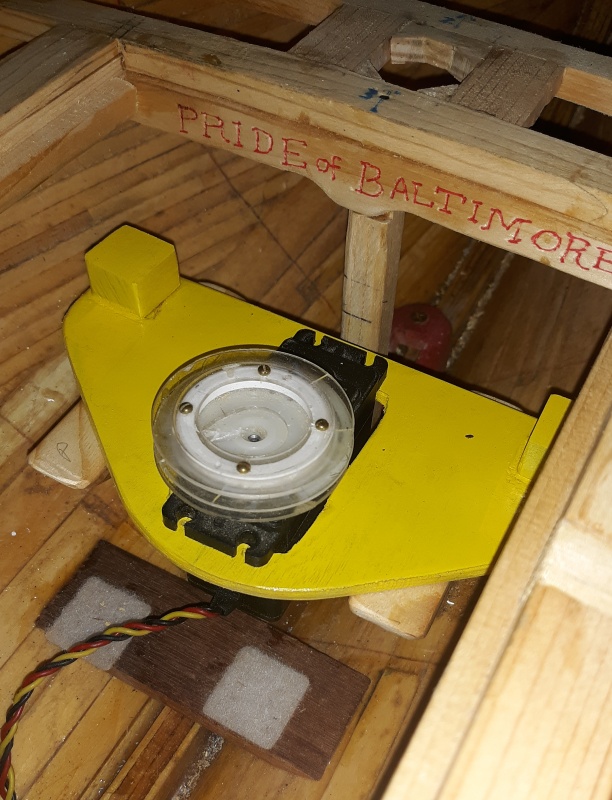

I left in the old rudder servo mounting blocks forward, and raised them with additional blocks reangled so the forward winch will align with the aft winch. The fastening holes will be slotted so the tray can slide for and aft to adjust the tension on the loops.

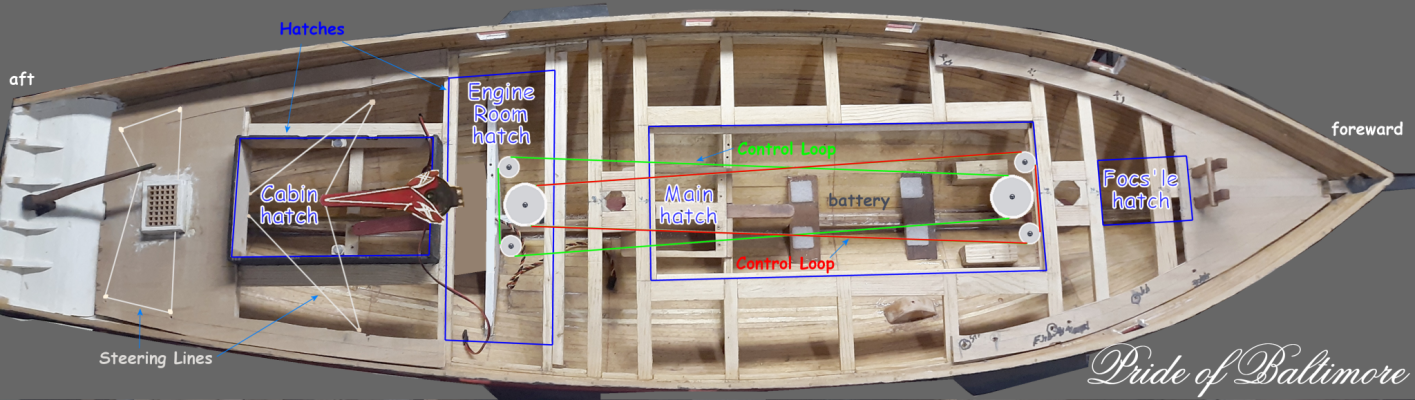

So here's a look at access into the hull with the deck in place and the hatches open. The little hatch up forward isn't needed and will get decked over. In RC models, how much room is in the hull isn't usually the problem, it's being able to access it through deck hatches. That was the main problem with the prior sail-control idea; it would have been near impossible to get at the parts of it where ajustments or repairs would be needed. 7/2: Found a nice pulley on Thingiverse, scaled it to one inch, and printed 4 of them. Mounted them with #8x1" wood screws with a brass washer under each one. We'll see how long they last.

The slots in the forward winch tray allow it 3/8" (1cm) of adjustment fore-and-aft.

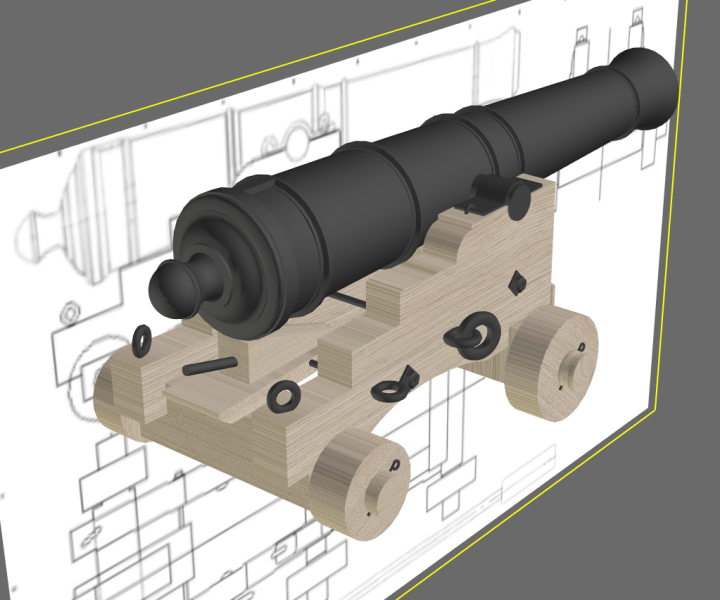

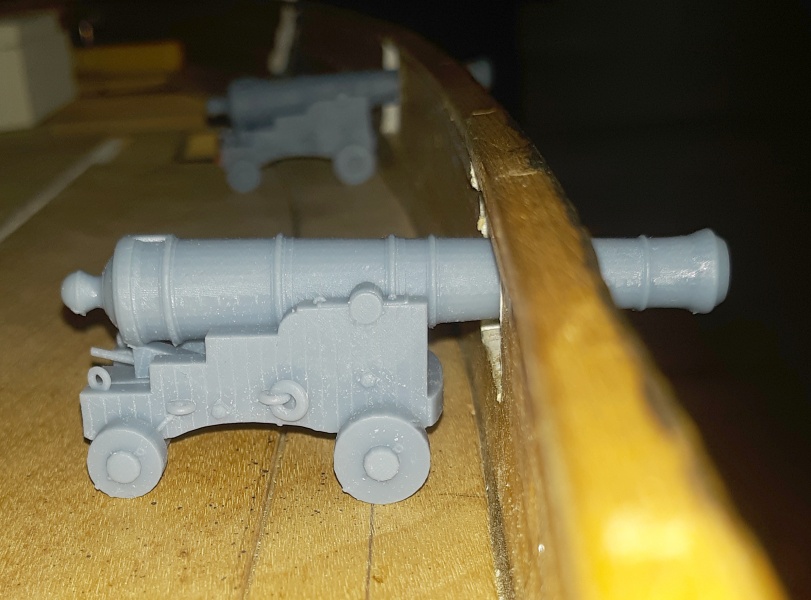

7/6: I started to modify the 3D model of Macedonian's 18 pounder to fit Pride but removing the cascabel ring, ER cartouche, and rearranging the bands to match Pride's guns was more work than just starting from scratch.

So I started from scratch, on the barrel anyway; the carriage I rearranged to fit.

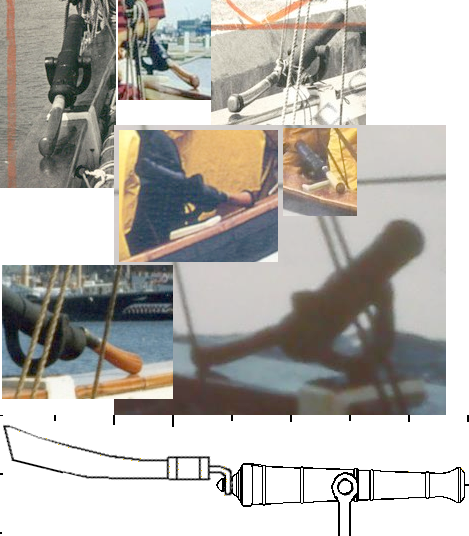

7/7: The great guns a success, I went on to the swivel guns. I couldn't find any good images of the original Pride's swivels, but what I could see was they were pretty much the same gun as the 6 pounders, scaled down. So that's what I did, scaled down my 6 pounder 3D model, added in the stock and yoke, posed it the way the gun usually looked, with the stock sitting on the rail, and printed two of them. |

||