8/11/2011

|

|

|

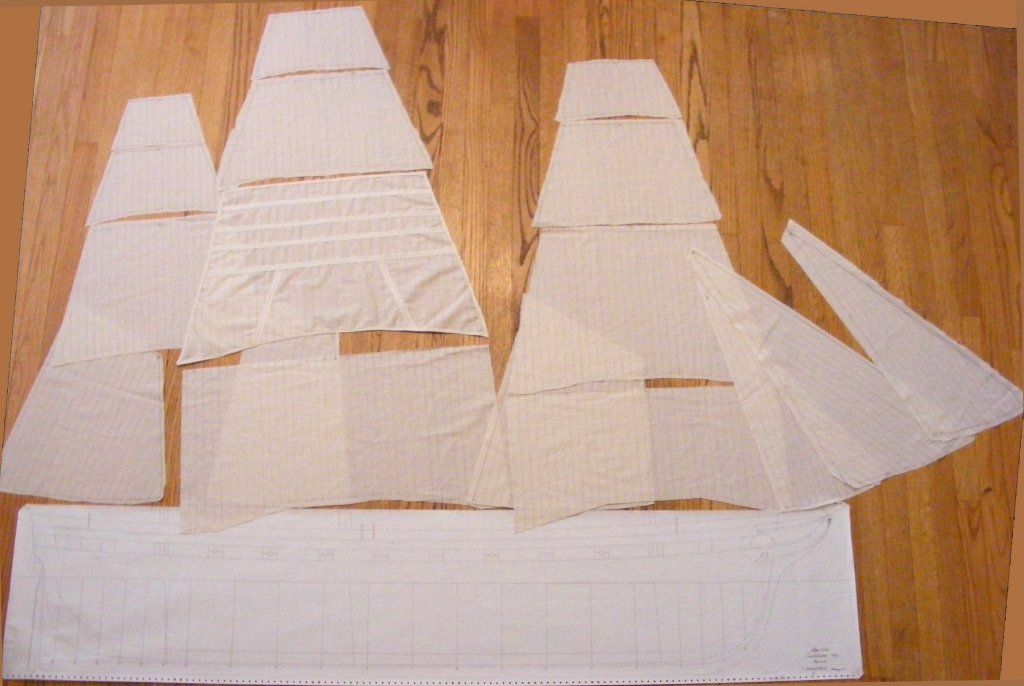

Previous Page | Next Page | Table of Contents click pictures for a larger version The little fellow in with the gun is Ivan, Constellation's first crewman. He's a 1:35 scale WWII Soviet sailor that's now an 1850's US sailor. He and some of his brethren of the sprue are going to be reworked into somewhat generic sailor figures that I will make a mold from to cast some 30-40 more crewmen to bring a little life to Constellation's decks. For the moment though, Ivan serves to give a sense of scale to things like, the guns. I'm not all that pleased with his paint job. It's a method I found on a figure painting website that looked good there, but I think I need to work at it a little more to get Constellation's crew to look sharp. There's gonna be Marines as well, or my friend Tommy in the picture below wouldn't forgive me. Sail Making Constellation is the last warship designed and built by the US Navy without an engine. As this is a working model of that ship, her sails are obviously a significant part of the project. I initially intended to use muslin for her sails. At this scale muslin's texture and weight were good.. but Dan Lewandowski, again, pointed me toward the cloth used in the SC&H kits; DuPont Supplex. Supplex is used in outdoor wear; windbreakers, rain gear, etc. It's light, strong, water resistant, UV resistant, and comes in various colors and weights. Being a synthetic gives it another feature over muslin - it melts. No, that's a good thing! Because it melts, I can seal the edges against fraying, and make holes for reef points with a soldering iron that are instant sealed grommets. With the muslin I guessed I might get 3-5 years of use out of them before UV and salt water made them unusable. Dan's Syren has been sailing for nearly 5 years with no sign of deterioration. Sails cut from new cloth - 1 foot rule in the center of the picture, mizzen tops'l below it: The first sail I made in the new material was the mizzen topsail. Instead of stitching the panel seams, they were ruled with a .03 permanent marker on both sides of the cloth. Stitching without causing the cloth to pucker along the stitch-line is more work than it's worth. Drawn seams were good enough for Mowll's Warrior, they're good enough for me.

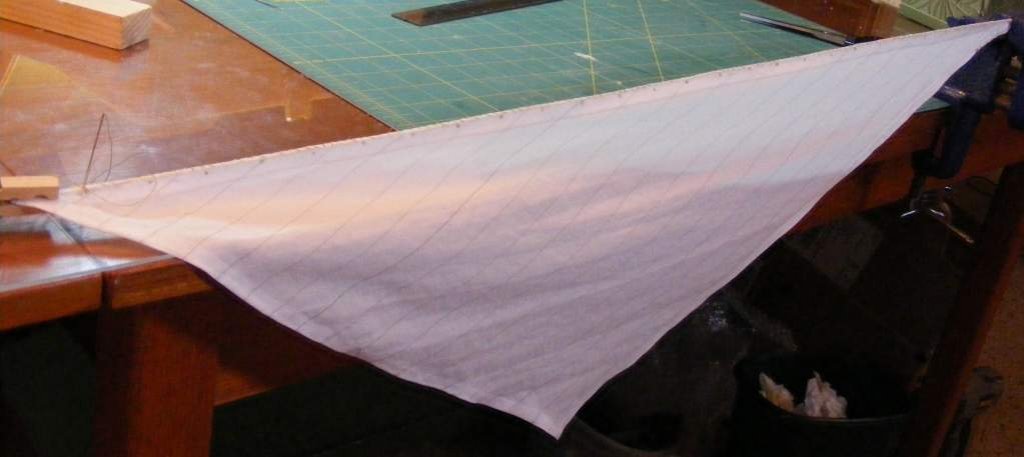

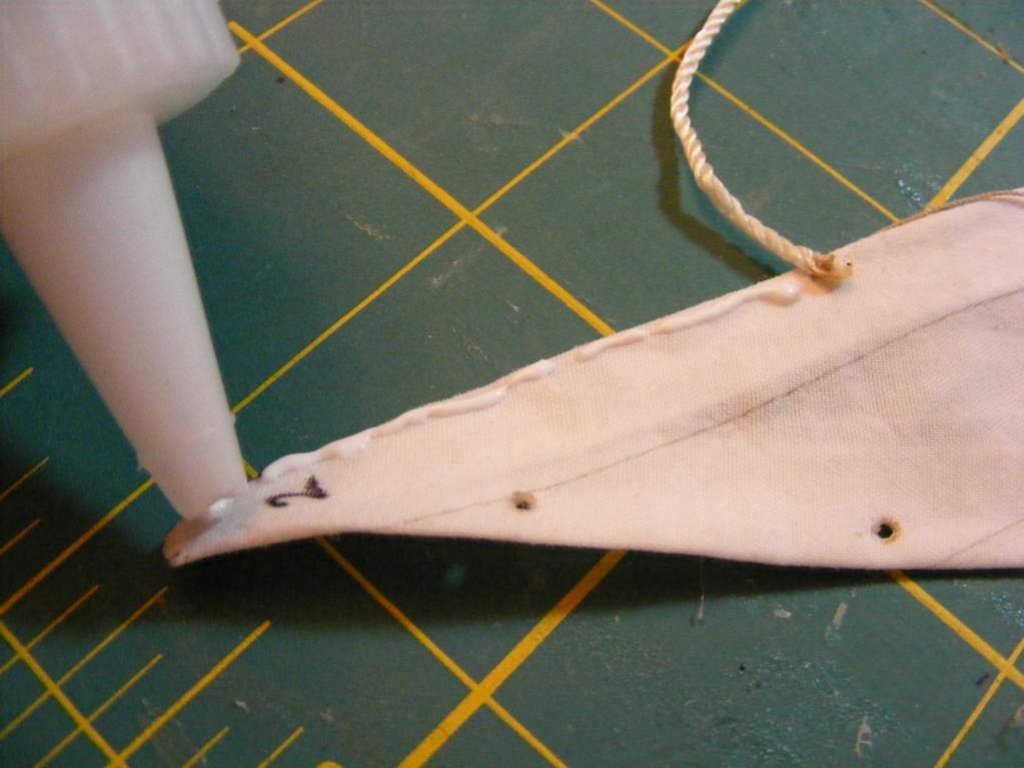

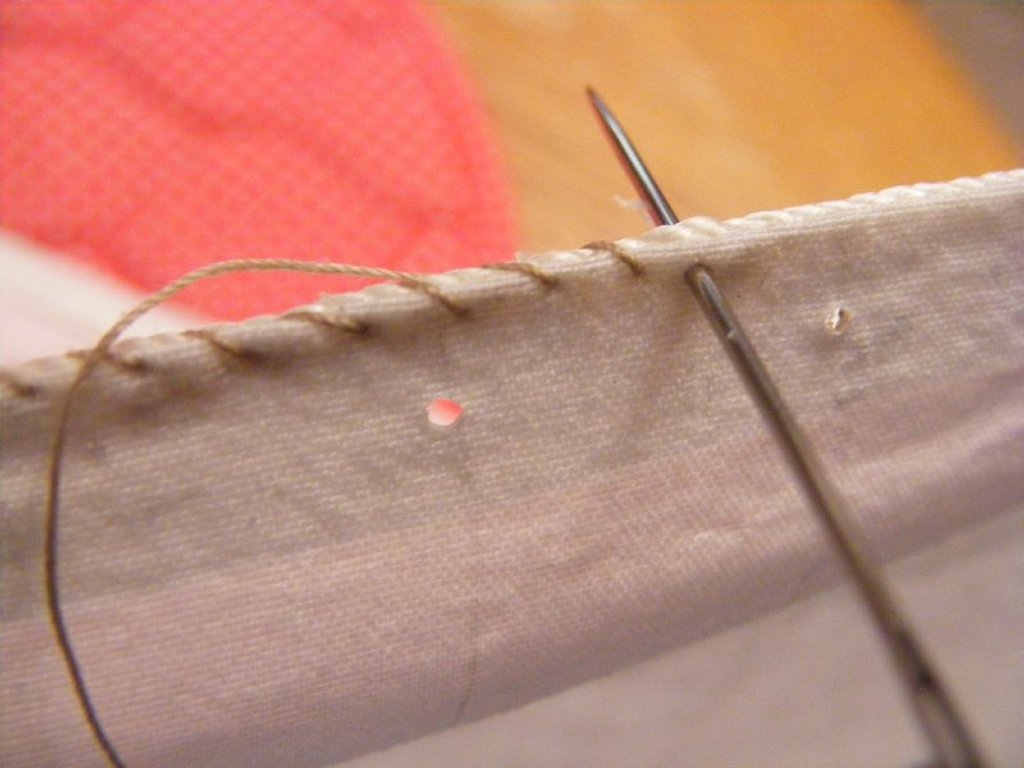

I'm not that trusting a soul, so when I attached the boltrope, I didn't just glue it, I also sewed it on, in fact, that's the only sewing done on the sails. The boltrope is nylon and will stretch more than the cloth will, without shrinking and deforming the sail. I clamped one end of the sail in a vise, and hung a little bit of weight from the other end of that edge to keep the sail taut without overly stretching it. I would fix the end of the boltrope then glue and stitch about 2 inches at a time. Eyes were formed at reef cringles, ear-rings, clews, etc, by taking a turn around a 1/16" dowel (actually a round wooden toothpick) and stitching it down. While all 17 of the sails are cut out, at the moment only the 5 sails I needed for her first test sail are near complete - that is, complete except for installing a zillion reef points. |

||

|

|